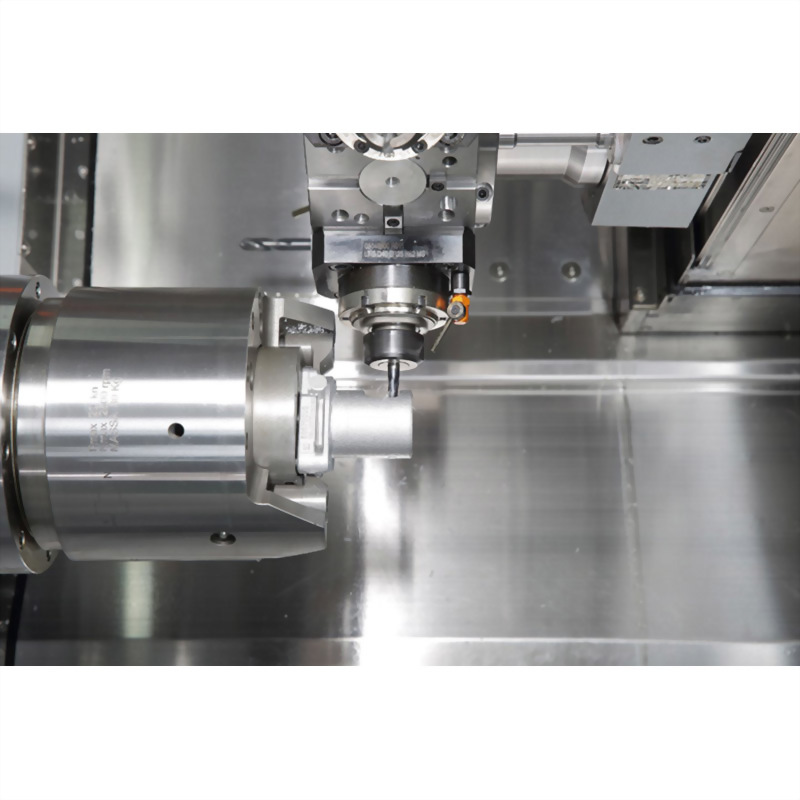

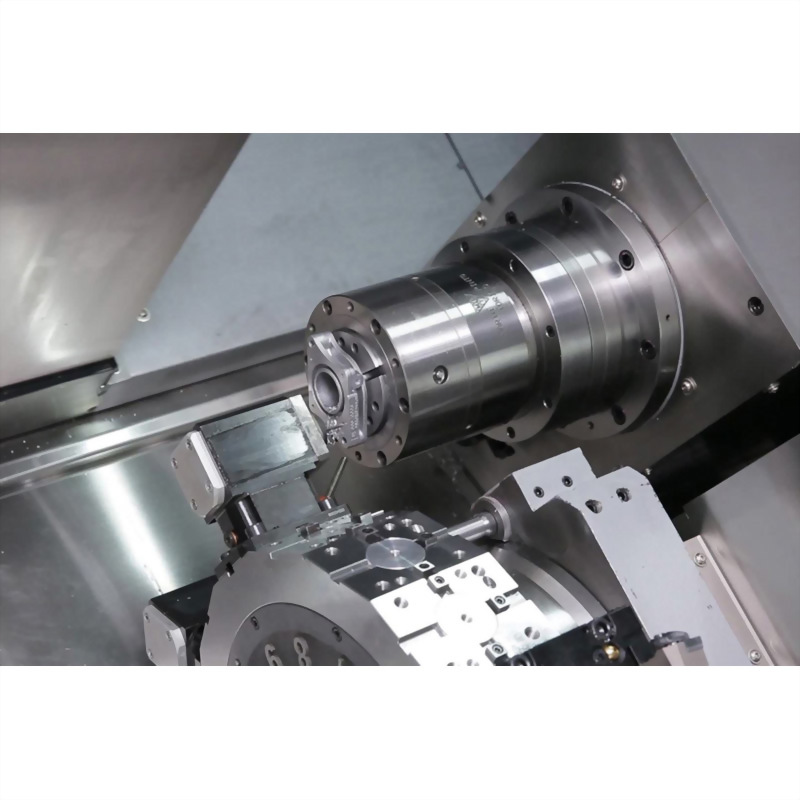

UZ-2000T2M

Multi-axis Complex Turning-milling Center

| ITEM/MODEL | UZ-2000T2M | ||||

| Controller | FANUC 0i-T | ||||

| CAPACITY | |||||

| Swing over bed | mm | 660 | |||

| Swing over saddle | mm | 620 | |||

| Max. Turning Diameter (SP1) | mm | 320 | |||

| Max. Turning Diameter (SP2) | mm | 320 | |||

| Max. turning length | mm | 790 | |||

| Guide way type | Linear + Box | ||||

| SPINDLE 1 | |||||

| Spindle Nose | ASA | A2-5 | A2-8 | A2-11 | |

| Chuck Diameter | inch | 6 | 10 | 15 | |

| Bar Capacity | mm | 52 | 78 | 105 | |

| Spindle Speed | rpm | 5000(Built-in) | 3500(Belt) | 2500(Belt) | |

| Spindle Motor Power(Cont. /30min) | kW | 11/15 (15/18.5) | |||

| SPINDLE 2 | |||||

| Spindle Nose | ASA | A2-5 | A2-6 | ||

| Chuck Diameter | inch | 6 | 8 | ||

| Bar Capacity | mm | 52 | 65 | ||

| Spindle Speed | rpm | 5000(Built-in) | 4500(Built-in) | ||

| Spindle Motor Power(Cont. /30min) | kW | 11/15 | |||

| TRAVELS | |||||

| X1/X2 axis Travel | mm | 210 | |||

| Z1/Z2 axis Travel | mm | 840 | |||

| Y-axis Travel | mm | - | |||

| B-axis Travel | mm | 920 | |||

| FEED RATES | |||||

| X1/X2 axis Rapid Traverse Rate | m/min | 30 | |||

| Z1/Z2 axis Rapid Traverse Rate | m/min | 40 | |||

| Y-axis Rapid Traverse Rate | m/min | - | |||

| B-axis Rapid Traverse Rate | m/min | 40 | |||

| TURRET | |||||

| Tooling system | BMT-40 | ||||

| Turret driven type | Servo mechanical | ||||

| Number of tools | station | 16+16 | |||

| Square tool shank size | mm | 20 | |||

| Round tool shank size | mm | 32 | |||

| Max. Rotary Tool Speed | rpm | 6000 | |||

| Rotary Tool power | kW | 3.7/5.5 | |||

| DIMENSION | |||||

| Machine dimension L x W xH | m | 4.7 x 2.4 x 2.4 | |||

| Net weight | kg | 10500 | |||