|

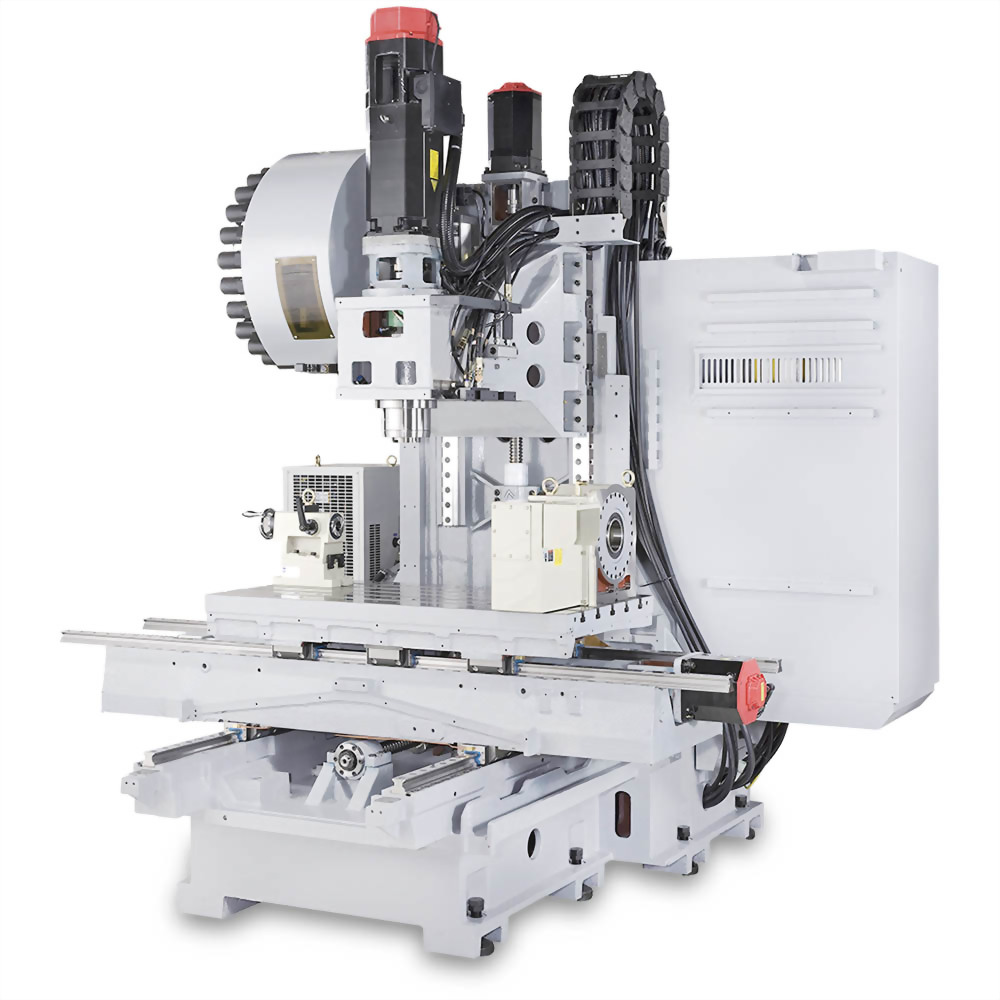

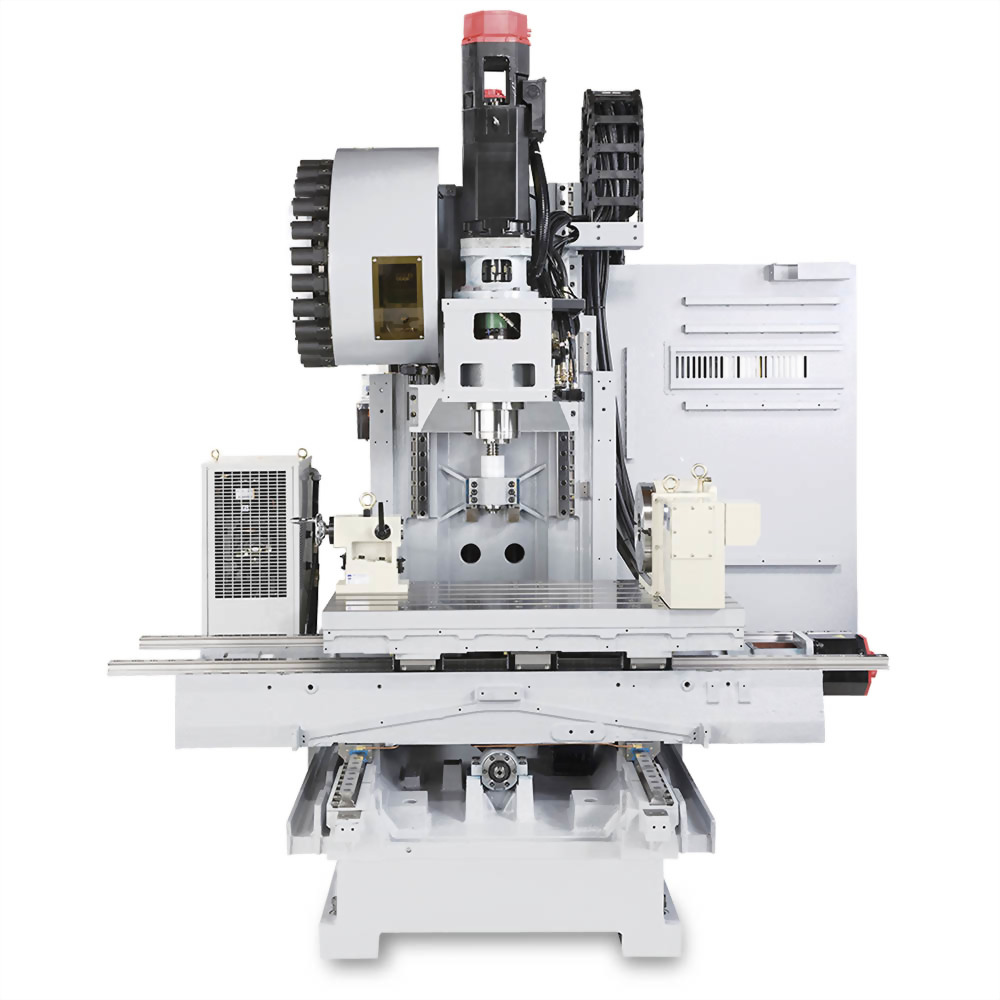

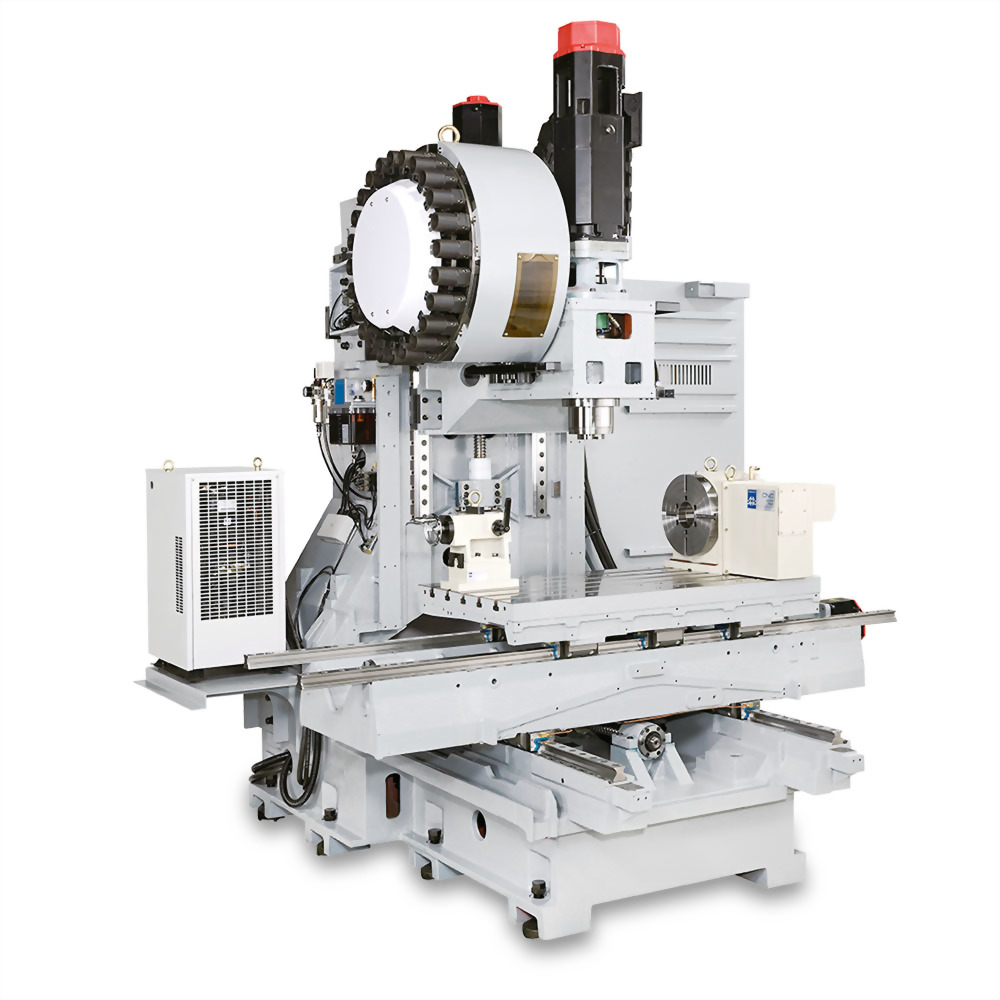

ITEM/MODEL

|

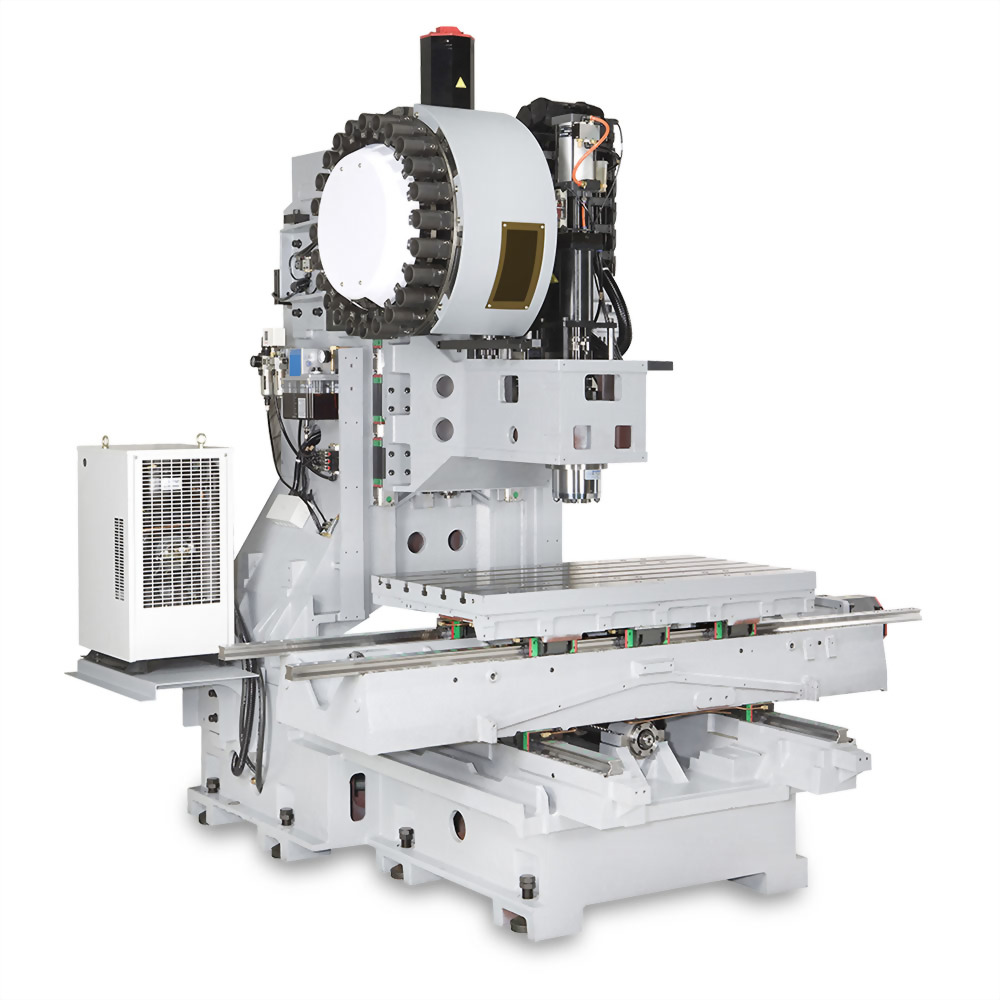

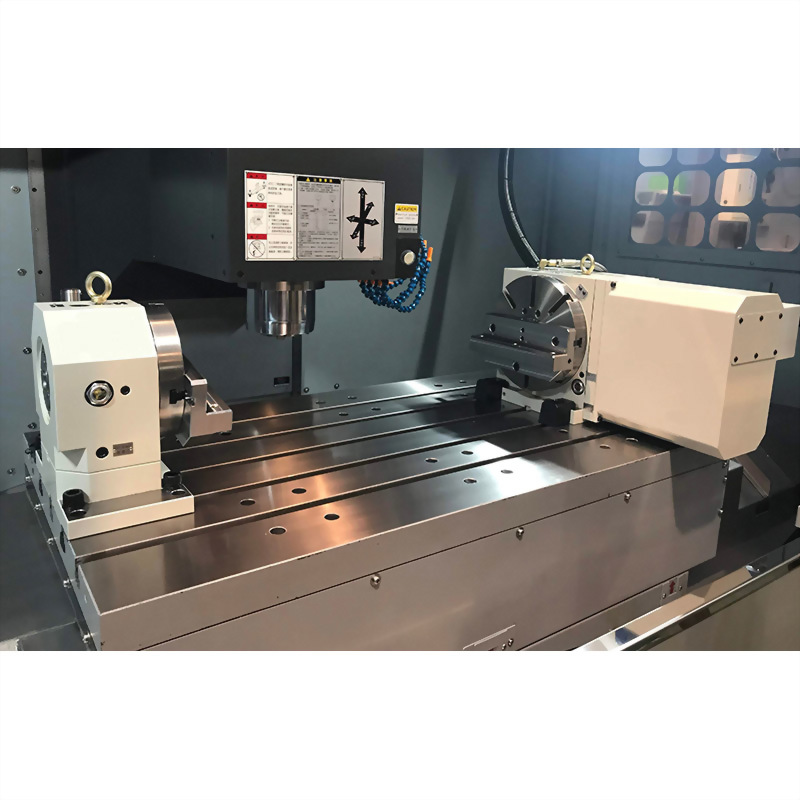

UM-120

|

|

Controller

|

|

FANUC 0i-M

|

|

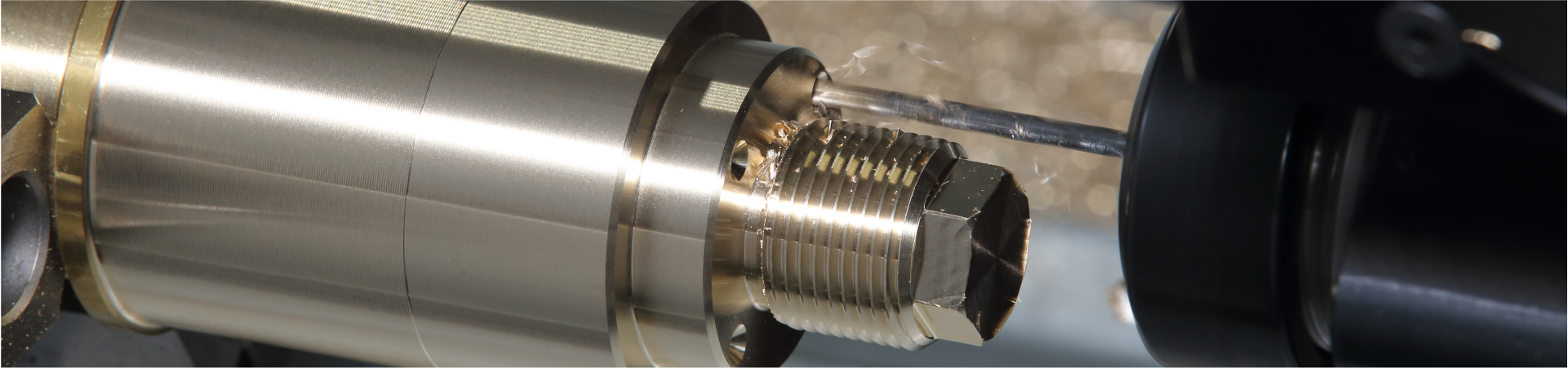

SPINDLE

|

|

Spindle speed

|

rpm

|

10000(12000)

|

|

Spindle nose

taper

|

BT40

|

|

Bearing

inner diameter

|

mm

|

70

|

|

Drive system

|

Belt(Direct)

|

|

TRAVELS

|

|

X-axis travel

|

mm

|

1200

|

|

Y-axis

travel

|

mm

|

650

|

|

Z-axis

travel

|

mm

|

600

|

|

Spindle

nose to table

|

mm

|

125~725

|

|

TABLE

|

|

Table dimension

|

mm

|

1200 x 600

|

|

T-slot(No.

of T-slot x width x pitch)

|

mm

|

5 x 18 x 100

|

|

Max.

weight on table

|

kg

|

1300

|

|

FEED RATES

|

|

X-axis Rapid Traverse

Rate

|

m / min

|

30

|

|

Y-axis

Rapid Traverse Rate

|

m / min

|

30

|

|

Z-axis

Rapid Traverse Rate

|

m / min

|

30

|

|

Cutting

feed rate

|

m / min

|

12

|

|

Ball

screw diameter (X/Y/Z)

|

mm

|

45/45/45

|

|

Guideway

bearing type

|

Ball

|

|

AUTOMATIC TOOL

CHANGE SYSTEM

|

|

Tool magazine capacity

|

pcs

|

24 (30/32)

|

|

Max. tool

weight

|

kg

|

7

|

|

Max. tool

diameter

|

mm

|

75

|

|

Max. tool

diameter without adjacent tools

|

mm

|

150

|

|

Method of tool

exchange

|

Arm type

|

|

Max. tool

length

|

mm

|

300

|

|

MOTOR

|

|

AI contour

control

|

AICC I (AICC II)

|

|

Spindle

motor power(Cont./30min)

|

kW

|

7.5/11 (15/18.5)

|

|

X/Y/Z

feed motor X, (Y/Z)

|

kW

|

3/3/4

|

|

Coolant

pump motor(50Hz/60Hz)

|

kW

|

0.75+1.27(1.01+1.73)

|

|

OTHERS

|

|

Air supply

|

kg/cm²

|

5.5

|

|

Machine

dimension L x W x H

|

m

|

3.1 x 2.3 x 2.8

|

|

Net

weight

|

kg

|

7500

|

|

|

|

|