UT-300L/UT-300LM

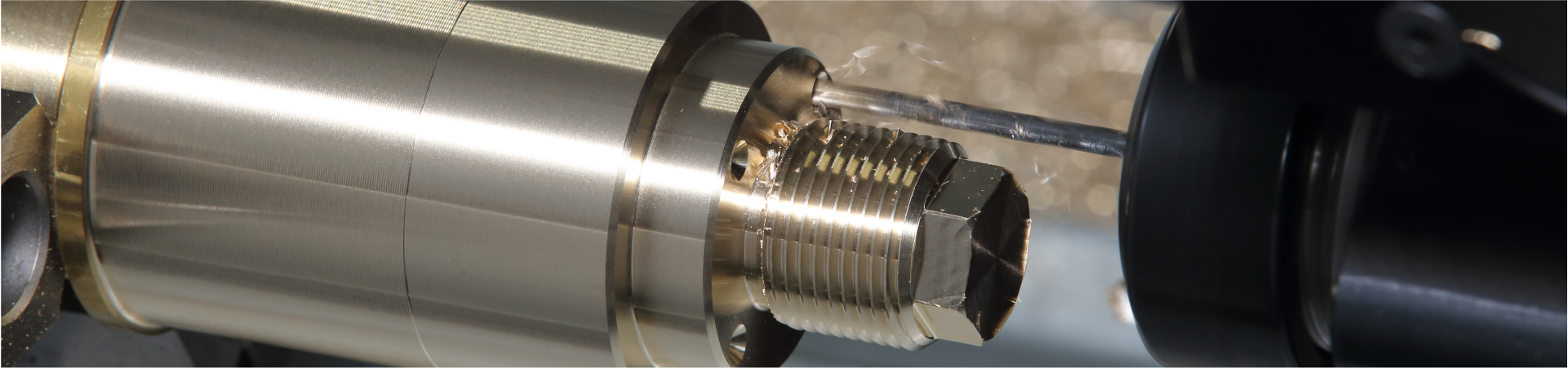

Slant Bed Turning Center

| ITEM/MODEL | UT-300L | UT-300LM | |||||||

| Controller | FANUC 0i-T | ||||||||

| CAPACITY | |||||||||

| Swing over bed | mm | 612 | 612 | ||||||

| Swing over saddle | mm | 400 | 400 | ||||||

| Max. turning diameter | mm | 500 | 420 | ||||||

| Max. turning length | mm | 1180 | 1100 | 1040 | 960 | ||||

| Guide way type | Box | ||||||||

| SPINDLE | |||||||||

| Spindle nose taper | ASA | A2-8 | A2-11 | A2-8 | A2-11 | ||||

| Chuck diameter | inch | 10 | 12 | 15 | 10 | 12 | 15 | ||

| Bar capacity | mm | 75 | 90 | 105 | 116.5 | 75 | 90 | 105 | 116.5 |

| Spindle speed | rpm | 3500 | 2700 | 2500 | 2000 | 3500 | 2700 | 2500 | 2000 |

| Spindle motor power(Cont. / 30min) | kW | 15/18.5 (18.5/22) | |||||||

| TRAVELS | |||||||||

| X-axis Travel | mm | 300 | 300 | ||||||

| Z-axis Travel | mm | 1250 | 1250 | ||||||

| Y-axis Travel | mm | - | - | ||||||

| FEED RATES | |||||||||

| X-axis Rapid Traverse Rate | m/min | 20 | 20 | ||||||

| Z-axis Rapid Traverse Rate | m/min | 24 | 24 | ||||||

| Y-axis Rapid Traverse Rate | m/min | - | - | ||||||

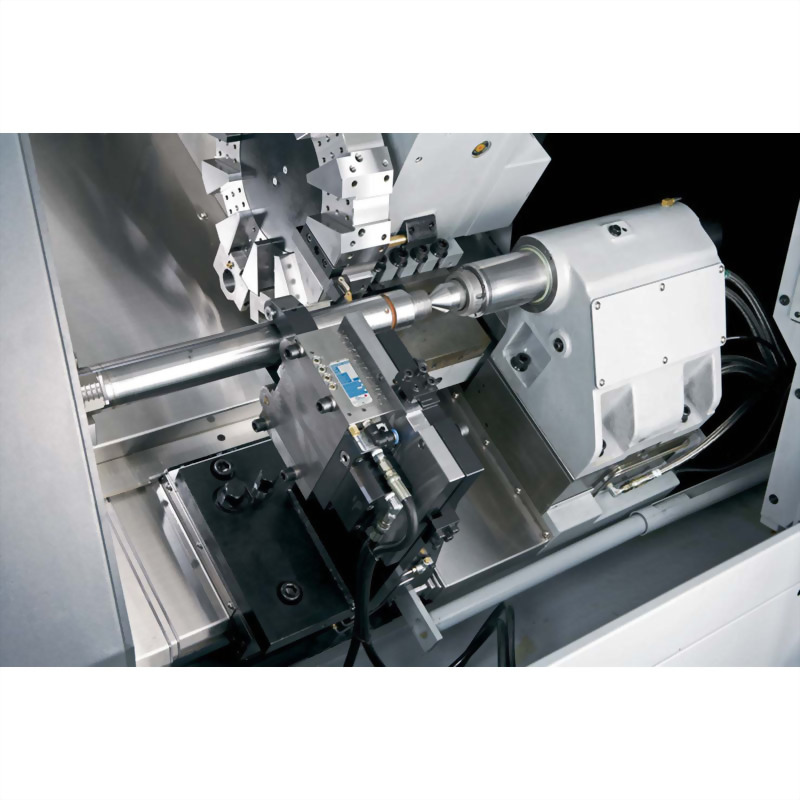

| TURRET | |||||||||

| Tooling system | BOT | BMT/VDI | |||||||

| Turret driven type | Hydraulic/Servo | Servo mechanical | |||||||

| Number of tools | station | 12 | 12 | ||||||

| Square tool shank size | mm | 25 | 25 | ||||||

| Round tool shank size | mm | 40 | 40 | ||||||

| Max. Rotary Tool Speed | rpm | - | 4000 | ||||||

| Rotary Tool power | kW | - | 3.7/5.5 | ||||||

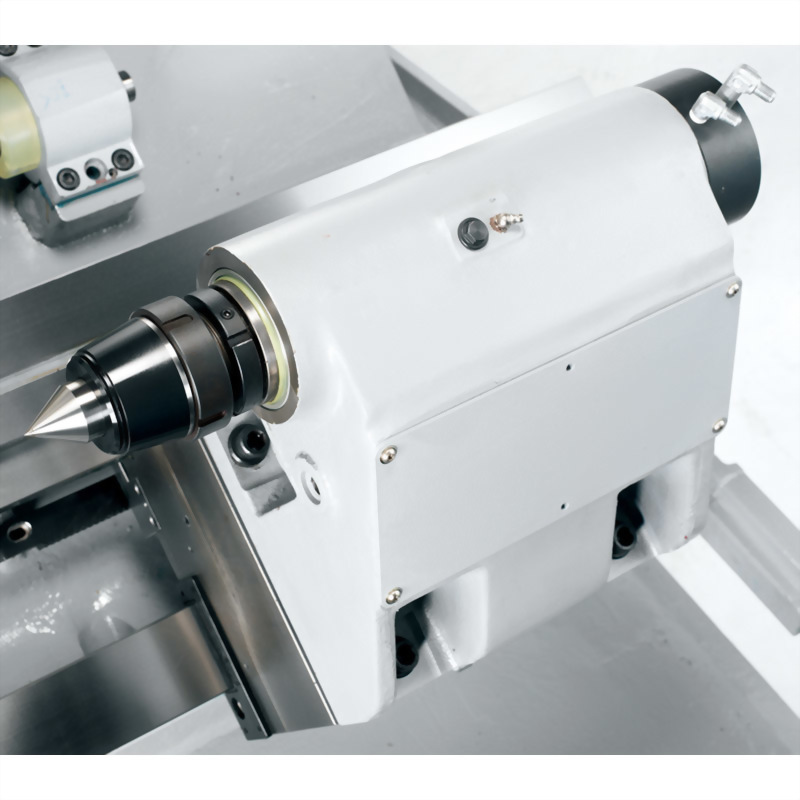

| TAILSTOCK | |||||||||

| Tailstock body travel | mm | 1040 | 1040 | ||||||

| Quill travel | mm | 120 | 120 | ||||||

| Quill diameter | mm | 110 | 110 | ||||||

| Quill taper | MT# | 5 | 5 | ||||||

| DIMENSION | |||||||||

| Machine dimension L x W x H | m | 4 x 1.8 x 1.8 | 4 x 1.8 x 1.9 | ||||||

| Net weight | kg | 6000 | 6000 | ||||||

| NO. | STANDARD ACCESSORIES | NO. | OPTIONAL ACCESSORIES |

| 1 | FANUC 0i-T controller | 1 | Upgrade to 15" Colored LCD monitor |

| 2 | RJ-45 interface | 2 | Collet chuck |

| 3 | Rigid tapping | 3 | Tool setter |

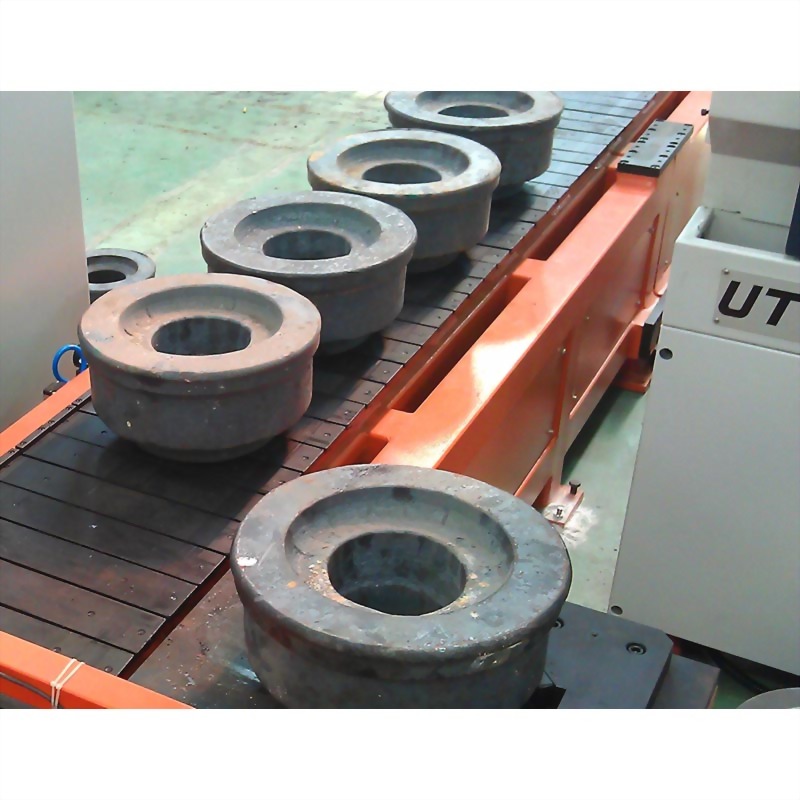

| 4 | Heat exchanger for electric cabinet | 4 | Parts catcher and parts conveyor |

| 5 | 10.4" Colored LCD monitor | 5 | Bar feeder interface (7 or 24 pins) |

| 6 | Lubrication system | 6 | Bar feeder |

| 7 | 4-bar coolant system | 7 | Oil mist collector |

| 8 | Three-color warning light | 8 | Oil-coolant skimmer |

| 9 | Air cooler for electric cabinet | ||

| 10 | Transformer | ||

| 11 | CE version | ||

| 12 | Loader interface | ||

| 13 | Gantry loader system | ||

| 14 | 0 degree rotary tool holder(UT-300LM) | ||

| 15 | 90 degree rotary tool holder(UT-300LM) | ||

| 16 | Auto door | ||

| 17 | Linear scale |