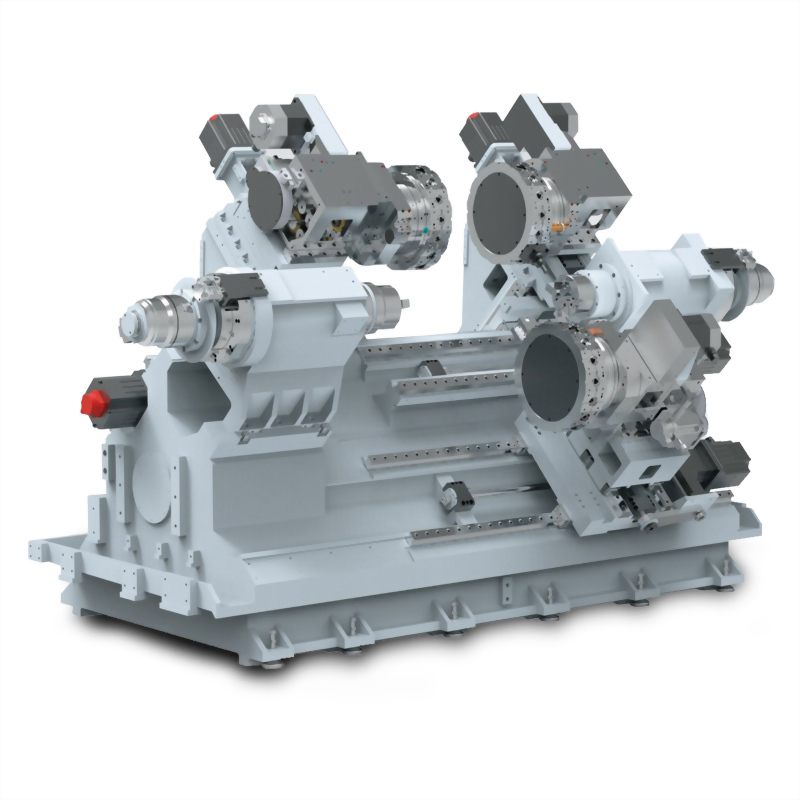

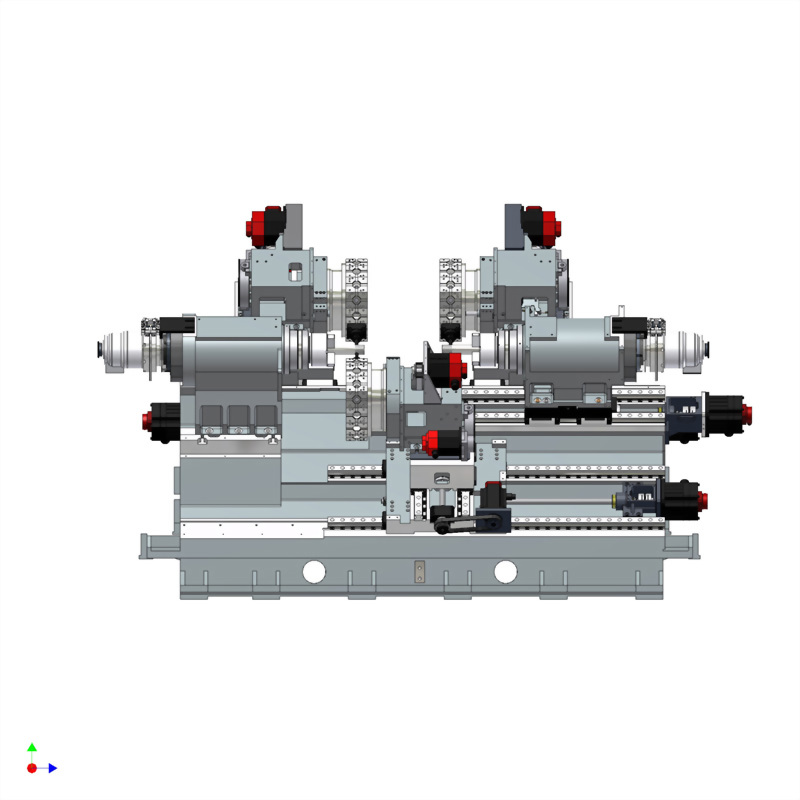

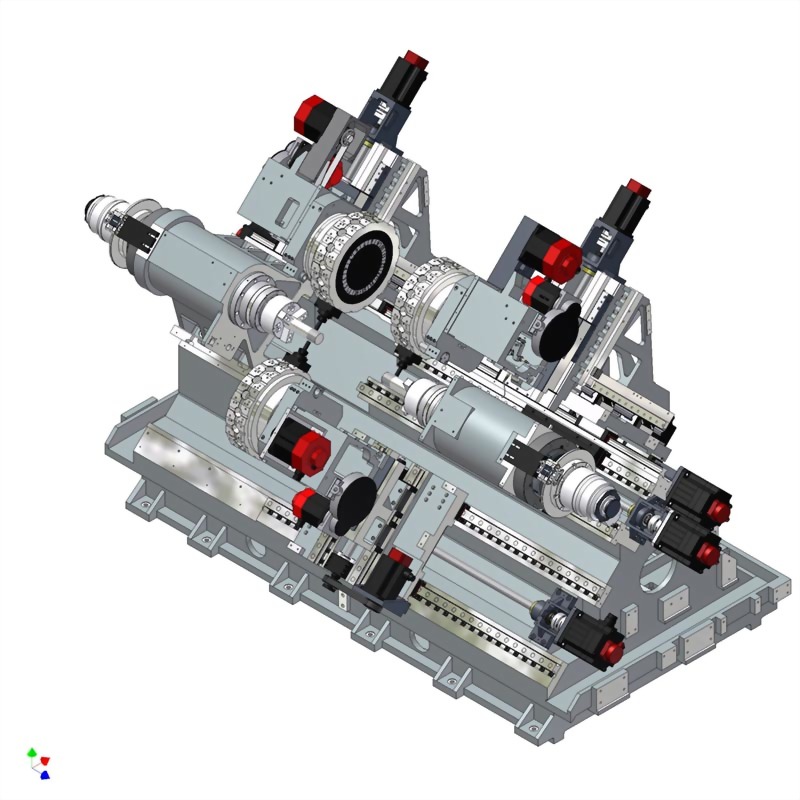

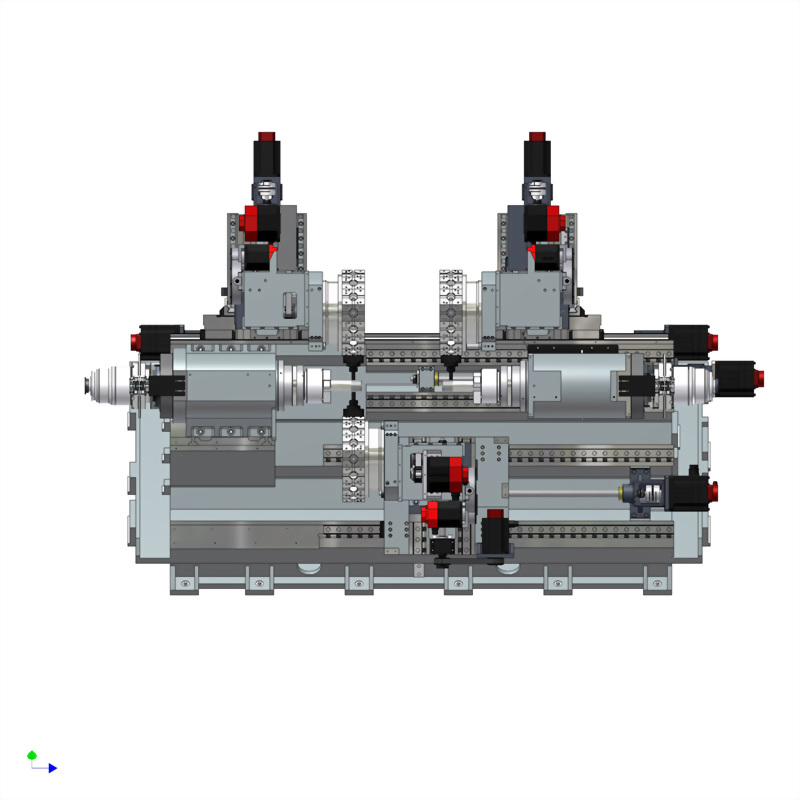

UZ-2000T3Y2

Multi-Axis Machine for Mass Production

| ITEM/MODOL | UZ-2000T3Y2 | |

| Controller | FANUC 0i-T | |

| Swing over bed | mm | 325 |

| Swing over saddle | mm | 325 |

| Max. Turning Diameter(Main-Spindle) | mm | 320 |

| Max. Turning Diameter(Sub-Spindle) | mm | 320 |

| Max. turning length | mm | 295 |

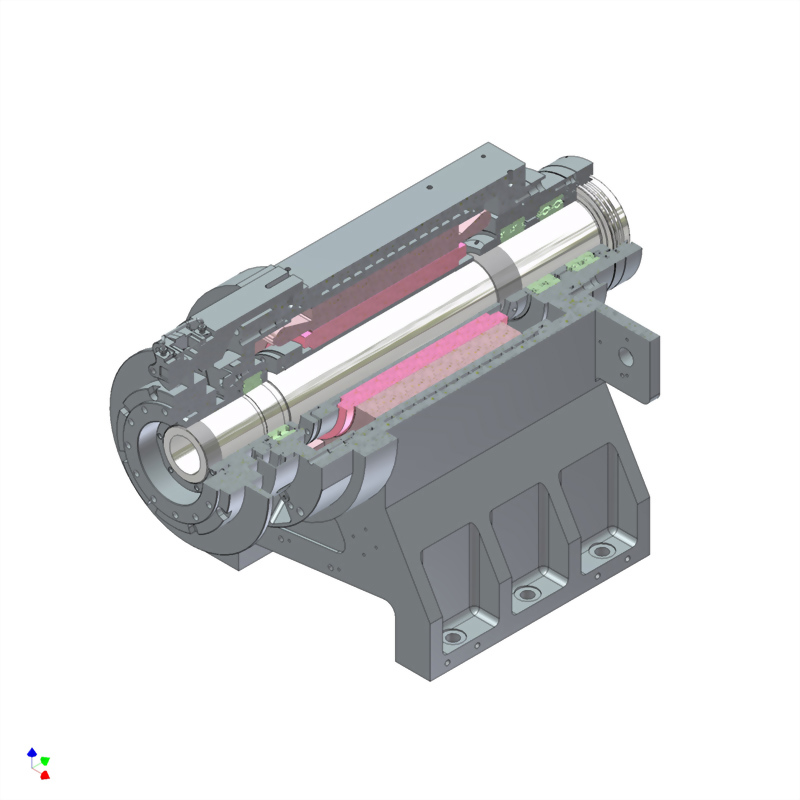

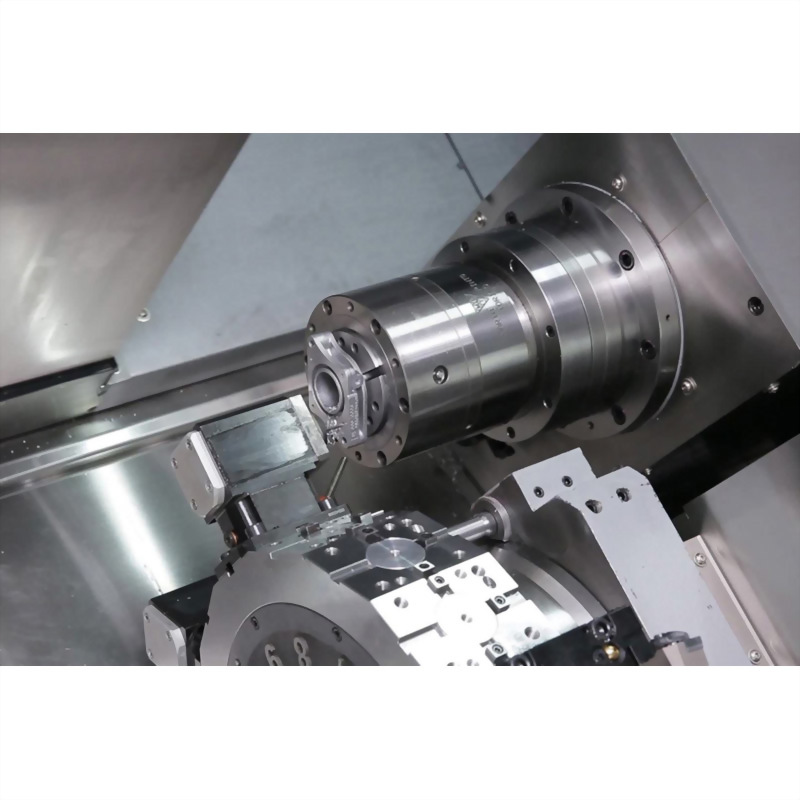

| MAIN SPINDLE | ||

| Spindle Nose | ASA | A2-5(A2-6) |

| Chuck Diameter | inch | 6(8) |

| Spindle Speed | rpm | 5000 / 4500 |

| Spindle Motor Power(Cont. /30min) | kW | 11/15 |

| Bar Capacity | mm | 52(65) |

| SUB SPINDLE | ||

| Spindle Nose | ASA | A2-5(A2-6) |

| Chuck Diameter | inch | 6(8) |

| Spindle Speed | rpm | 5000 / 4500 |

| Spindle Motor Power(Cont. /30min) | kW | 11/15 |

| Bar Capacity | mm | 52(65) |

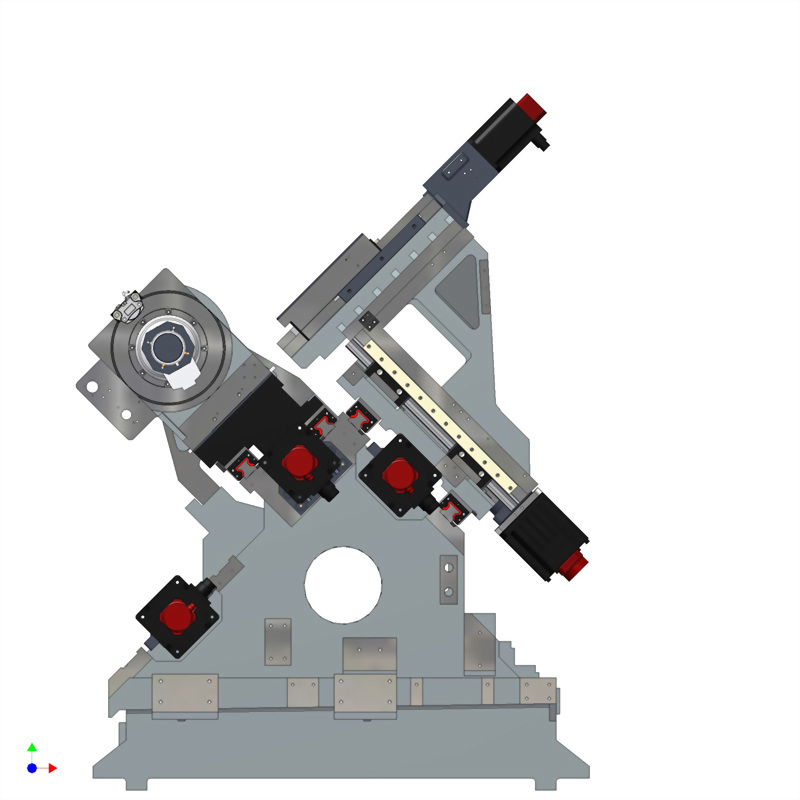

| TRAVELS | ||

| X-axis Travel | mm | X1/X2/X3:210 |

| Z-axis Travel | mm | Z1/Z3 : 350 , Z2 : 840 |

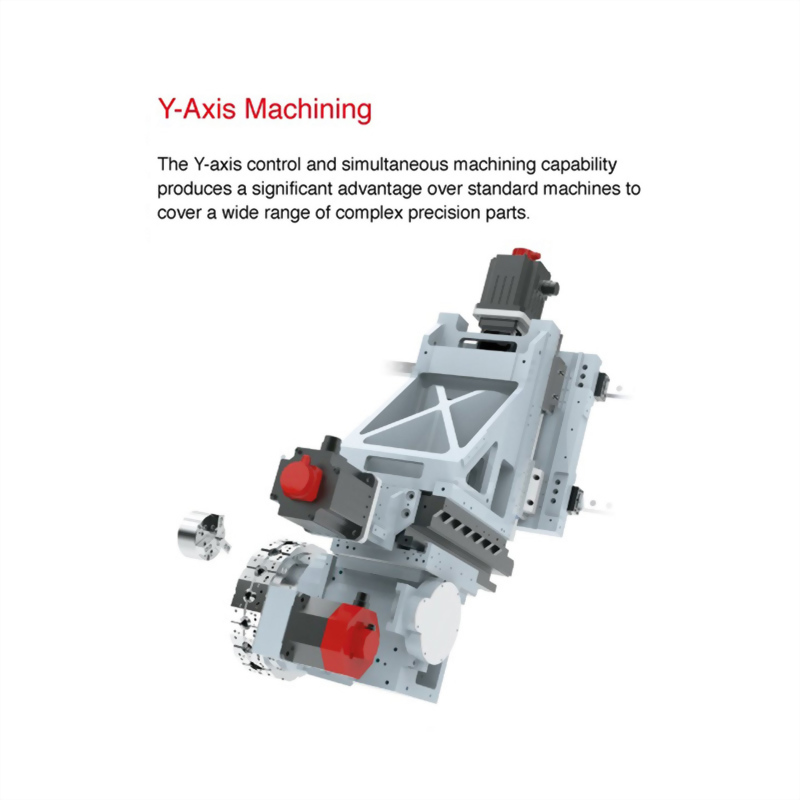

| Y-axis Travel | mm | Y1/Y3:+65/-45 |

| B-axis Travel | mm | 920 |

| FEEDS | ||

| X-axis Rapid Traverse Rate | m/min | 24 |

| Z-axis Rapid Traverse Rate | m/min | 40 |

| Y-axis Rapid Traverse Rate | m/min | 20 |

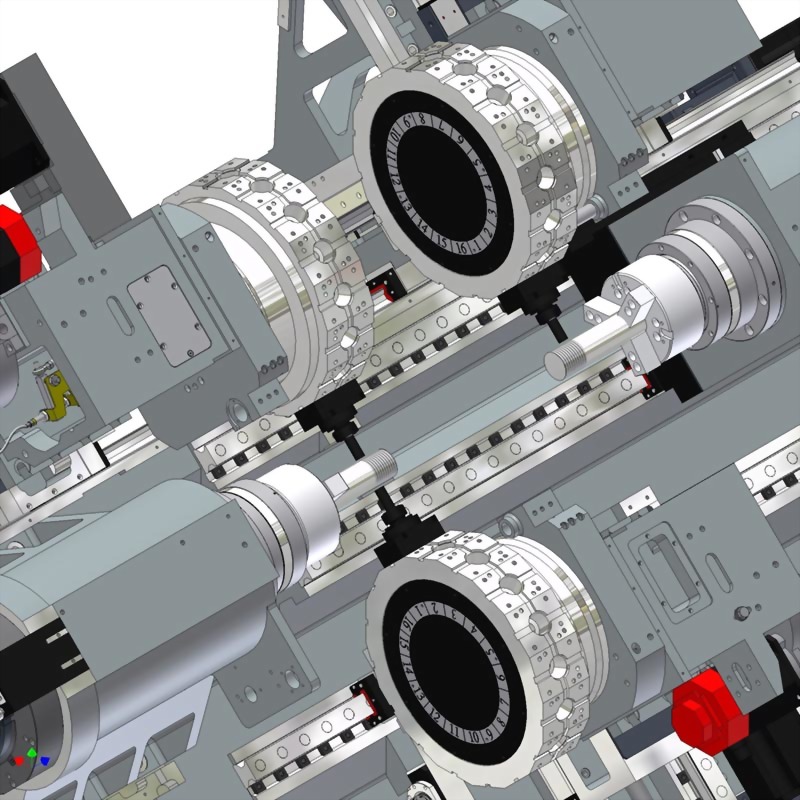

| TURRET | ||

| Tooling system | BMT 40 | |

| Turret driven type | Servo mechanical | |

| Number of tools | station | 16+16+16 |

| Square tool shank size | mm | 20 |

| Round tool shank size | mm | 32 |

| Rotary tool spindle power | kW | 4.5 |

| Rotary tool spindle speed | rpm | 6000 |

| DIMENSION | ||

| Machine dimension L x W x H | m | 4.7 x 2.4 x2.3 |

| Net weight | kg | 11500 |

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without prior notice. All the specifications shown above are just for reference.

| NO. | STANDARD ACCESSORIES | NO. | OPTIONAL ACCESSORIES |

| 1 | FANUC 0i-T controller | 1 | Unloader & conveyor for finished parts |

| 2 | RJ-45 interface | 2 | Upgrade to 15" Colored LCD monitor |

| 3 | Rigid tapping | 3 | Collet chuck |

| 4 | Heat exchanger for electric cabinet | 4 | Tool setter |

| 5 | 10.4" Colored LCD monitor | 5 | Parts catcher and parts conveyor |

| 6 | Lubrication system | 6 | Bar feeder interface (7 or 24 pins) |

| 7 | 4-bar coolant system | 7 | Bar feeder |

| 8 | Three-color warning light | 8 | Oil mist collector |

| 9 | Oil-coolant skimmer | ||

| 10 | Air cooler for electric cabinet | ||

| 11 | Transformer | ||

| 12 | CE version | ||

| 13 | Loader interface | ||

| 14 | Gantry loader system | ||

| 15 | Automatic door | ||

| 16 | Axial rotary tool holder | ||

| 17 | Radial rotary tool holder | ||

| 18 | Linear scale |