Quality Assurance

Precision 3D Inspection

High precision is the core to maintaining stable machining in machine tools. Therefore, we adhere to strict quality standards to ensure that every machine leaving the factory possesses excellent dimensional and geometric accuracy. Throughout the manufacturing and assembly process, we implement multiple high-standard precision inspection procedures. From lathes to machining centers, all critical structural components, such as the spindle box, base, turret seat, and tailstock, as well as essential core components like the spindle, tailstock quill, and turret internal transmission parts, must meet the stringent tolerances specified in the design drawings. These components undergo comprehensive dimensional inspection using precise 3D coordinate measuring machines (CMM) to ensure the highest quality.

Laser Interferometer Comprehensive Precision Inspection

To ensure exceptional precision under complex machining environments, we fully utilize laser interferometers for precise positioning error testing and compensation on linear and rotary axes, ensuring that all axial movements remain within the stringent ISO precision standards. This is particularly crucial for multi-axis turning-milling composite machines and five-axis machining centers, where precise linear and rotational accuracy calibration is required during complex polyhedral machining to effectively reduce machining errors and ensure that products meet high-quality standards.

Five-Axis Tool Tip Error Compensation

The Tool Tip Test on five-axis machines is used to verify and calibrate whether the tool center point (TCP) can accurately remain in the same position during multi-axis movements. The goal is to control the tool tip from shifting due to geometric errors or axis misalignment when rotating axes are involved. Without calibration, these errors can lead to inaccuracies in machining dimensions, particularly affecting high-precision or surface machining processes.

Circularity Accuracy Verification

Before each CNC machine leaves the factory, it undergoes circularity accuracy testing to verify the deviation between the actual motion trajectory and the ideal arc during multi-axis movements. Additionally, the synchronization and coordination of all participating axes during the motion process are also checked. The measured roundness variation must meet the company's quality standards and comply with the inspection methods and specifications of the ISO 230 series. Only after meeting these requirements can the machine proceed to the final delivery stage.

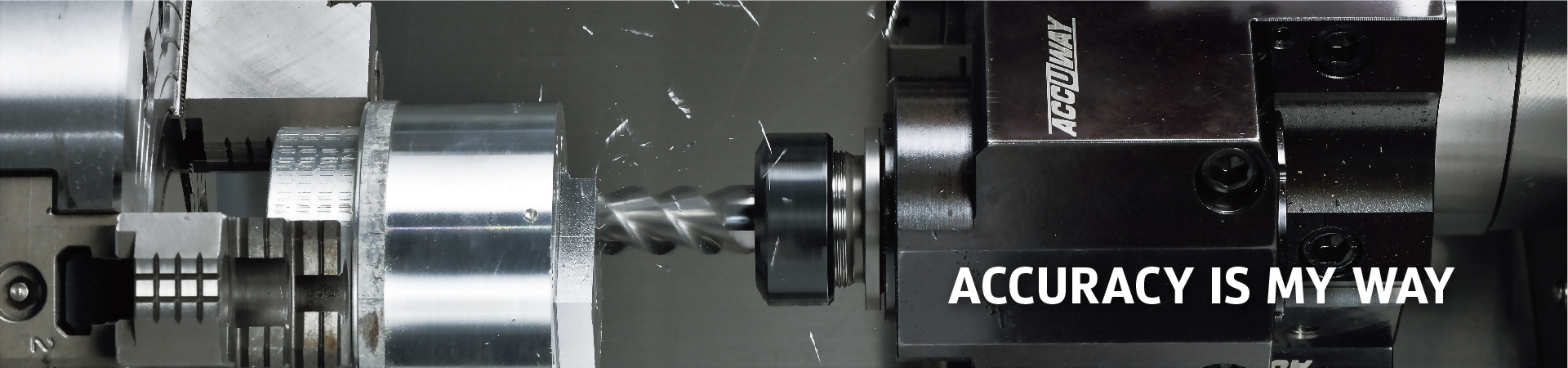

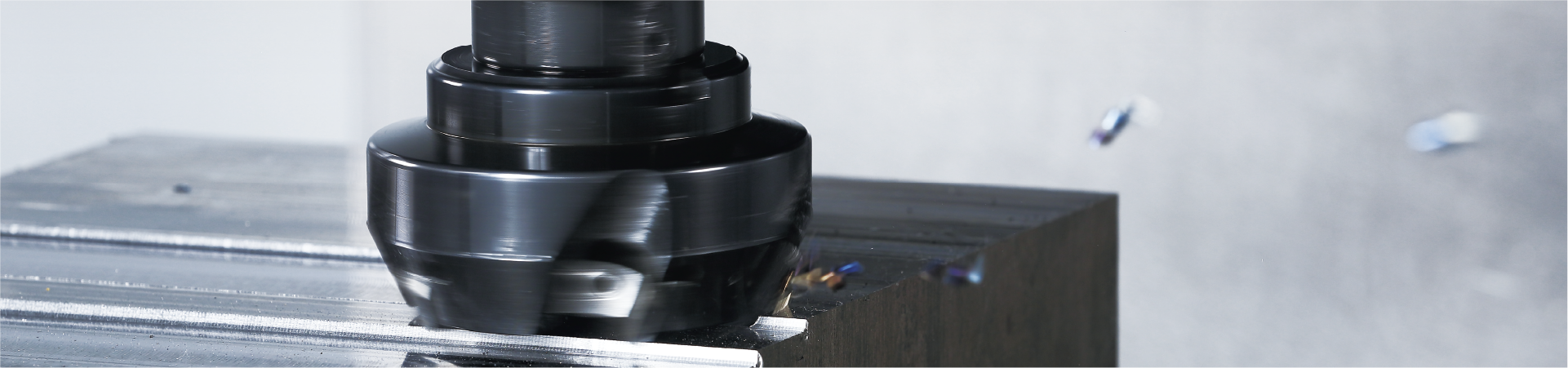

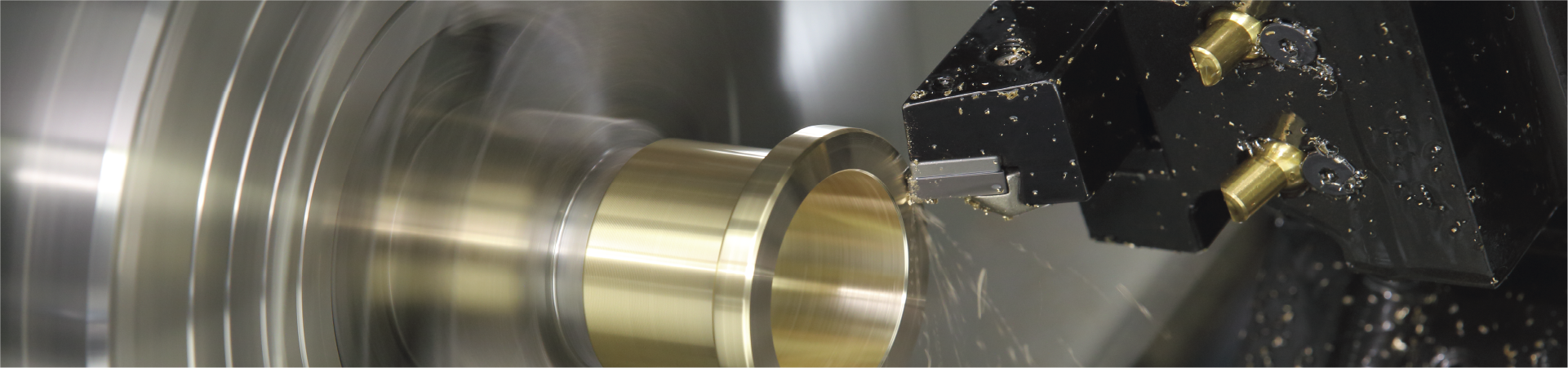

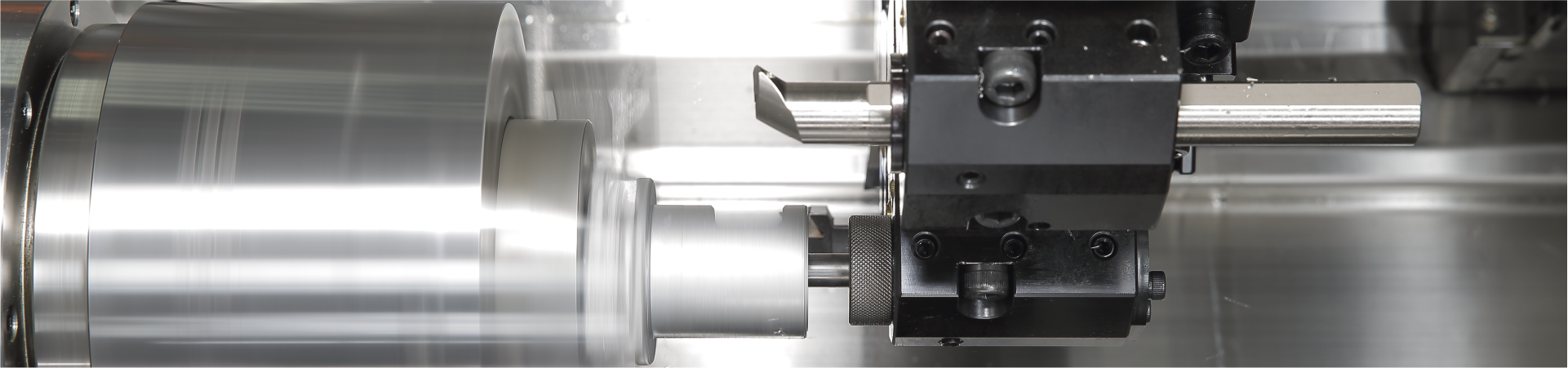

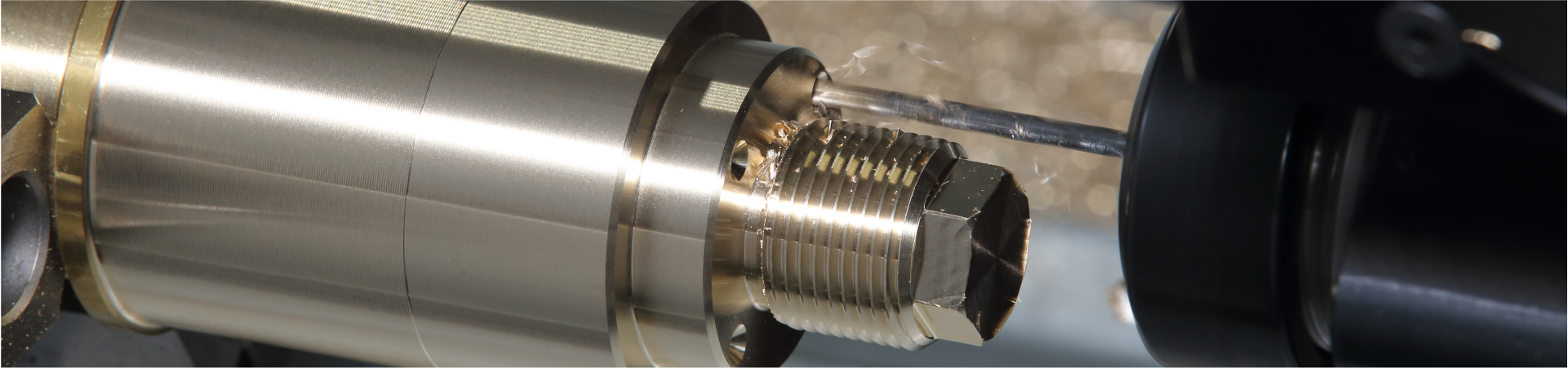

Dynamic Cutting Verification

As part of our quality verification process, we incorporate actual cutting tests by machining ISO standard workpieces to assess dimensional accuracy, surface roughness, and cutting stability. Through finished product inspections, we confirm the overall performance of the machine under dynamic machining conditions, using this as the basis for final quality approval to ensure that the machine can immediately meet customer production requirements after delivery.

Quality Policy

We are committed to delivering the highest quality, prioritizing customer requirement, pursuing continuous technological innovation, and upholding integrity in every aspect of our business.